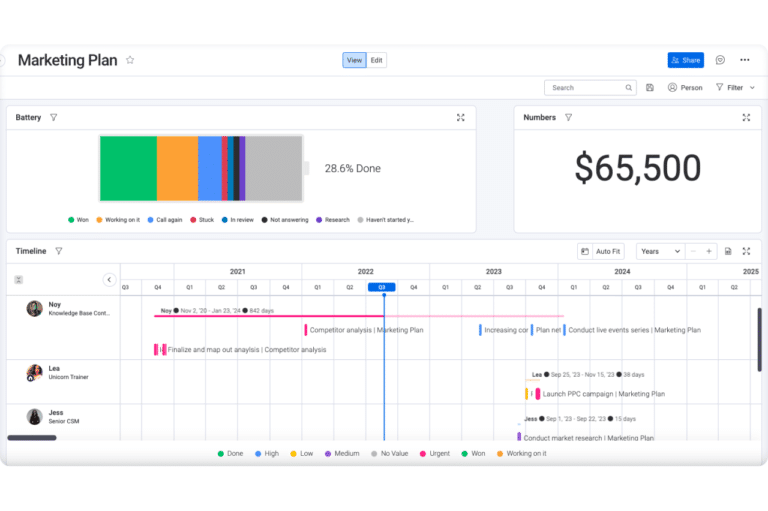

Information that reached specific departments didn’t pass on to other teams. In a huge number of tools used by the company, it was difficult to find the most recent data or subsequent iterations. Employees didn’t have one common place to process information and categorize it. This situation significantly hindered communication and delayed project implementation.

In addition, employees were burdened with many repetitive tasks that were often left out during the day. As a result, many updates were lost during the process. Therefore, the customer might have received an order that wasn’t what they expected. Transferring information between tools or assigning a task to another employee were very time-consuming.

The sales department had no insight into the tech data of the orders, and the technical department had no access to the sales information. This led to oversights. In addition, there was a problem resulting from unclear payment steps.

In the production of LED designs, especially personalized ones, the key is the inventory. In order to efficiently implement customer ideas, the technical department must have the resources to create luminous letters. Unfortunately, administrative and organizational issues weren’t systematized while the company lacked processes and a place to collect key documents. This was a big problem, especially in terms of onboarding another employee to perform administrative work.